Smarter Cleaning for Press Section Performance and Profit

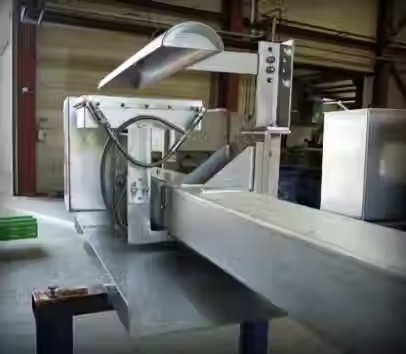

The PCF Press Felt Cleaner is a precision-engineered cleaning unit designed for the press section, placed in front of the vacuum boxes. Built entirely from AISI316 stainless steel, this system delivers powerful, uniform cleaning through a compact arrangement of fixed needle jet nozzles — all integrated into a single, high-efficiency unit.

Key Features:

Corrosion-resistant AISI316 stainless-steel construction

Compact unit design with integrated fixed needle jet nozzles

Positioned for maximum impact ahead of vacuum boxes

Efficiency That Enhances Output

By cleaning consistently across the full felt width with no overlap or striping, the PCF system ensures stable felt conditions, extending the usable life of press felts and minimizing paper defects and breaks.

Proven Water Savings

Compared to conventional oscillating showers, the PCF Press Felt Cleaner delivers dramatic reductions in water use:

Traditional Showers: 154 liters/minute

PCF Cleaner: 19.5 liters/minute

Annual Water Savings: 69,724 m³ per machine

These savings not only reduce your environmental footprint but also lead to lower water supply and wastewater treatment costs.

Lower Energy and Chemical Usage

With less water and more precise cleaning, the system helps reduce:

Electricity consumption due to lower pump demand

Chemical use, by preventing felt contamination and maintaining permeability

Press Performance You Can Count On

Optimizes moisture cross profile and felt dewatering capacity

Allows on-the-fly nozzle inspection without halting production

Helps reduce paper breaks, supporting smoother operations

Why Choose the PCF Press Felt Cleaner?

✔ Save over 69,000 m³ of water annually

✔ Extend felt life and reduce replacements

✔ Enhance press section efficiency and sheet quality

✔ Lower electricity and chemical costs

The PCF Press Felt Cleaner is the smart solution for sustainable, cost-efficient press section cleaning — delivering results that protect both your bottom line and the environment.